It is often said that a dull blade is more dangerous than a sharp one. You’d agree with us if you’ve ever made an inaccurate cut during a project just because the blade was dull.

Most people get a professional to sharpen a blade, but you can easily do it yourself too.

Sharpening a circular saw blade is easy and cost-effective. Here’s how we’ll do it:

Quick Summary

In this article, we will discuss the following things:

- How to sharpen a circular saw blade the easy way

- Safety measures, Tips, and FAQs for the step-by-step guide

Sharpening A Circular Saw Blade

All saw blades dull over time with constant usage. Once a blade is dull it no longer makes accurate and precise cuts.

If you are looking to make angled or beveled cuts then it is advised to never use a dull blade. Sharpening circular saw blades is easier than it looks.

Is Sharpening Circular Saw Blades Worth It?

The sharper the blade, the better the cut. Sharpening your circular saw blade is definitely worth it because it saves your projects from being sub-standard.

Many professionals offer their services in this regard but no one said you cannot do it on your own either.

Sharpening your blade will improve the quality of your cuts and protect your tool as well as save you money. If you know how to sharpen your blade, you will never need a professional again.

How Often Do You Have To Sharpen Saw Blades?

You have to sharpen circular saw blades depending on how much you use them and what kind of material they are being used on.

For example, if you use a blade to work ten hours a day every day, then it’ll need to be sharpened more than the blade you use five hours a day.

At the end of the day, some people sharpen blades every week whilst others sharpen them earlier or much later.

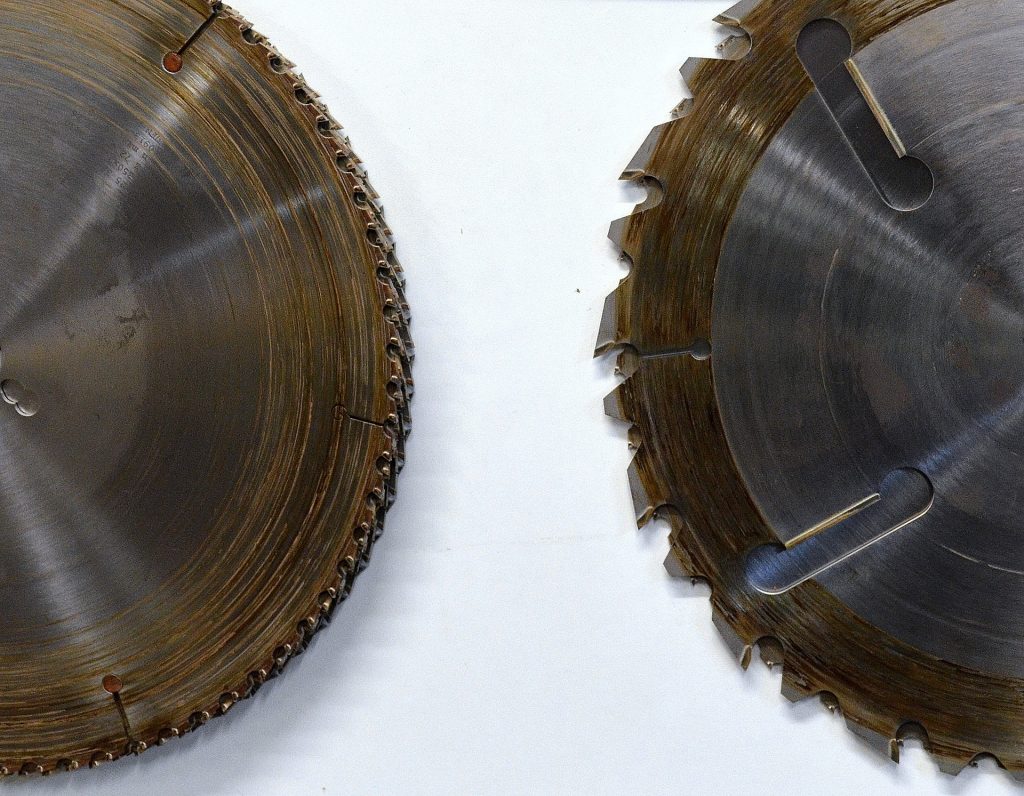

What Are The Different Types of Circular Saw Blades?

1. Metal Cutting Blade

This type of blade is specifically used for cutting through metal and allows, hence it has strong teeth and is wear-resistant.

2. Masonry Blade

These blades are also known as diamond blades. They are used to cut through stone and concrete.

3. Plastic Cutting Blade

With a greater number of teeth, these blades easily cut through plastic and synthetic materials.

4. Dado Blade

These blades with spaced teeth are used to cut grooves into the wood, however, they are illegal in some countries.

5. Treated Wood Blade

Treated wood blades are also known as general-purpose blades, they can cut through any wood material.

6. Combination Blade

Combination blades, as the name suggests, are used to cut a variety of materials. Their spaced and leaning teeth make it sharp and don’t let the material get stuck.

7. Kerf Blade

Kerf blades are used to make thin cuts in narrow boards and pieces of lumber.

8. Ripping Blade

These blades work with a rip fence and are used to cut along or with the grain of a wooden piece. The pieces are usually narrow.

9. Finishing Blade

You can use finishing blades to make clean and precise cuts that will be exposed once the project is completed.

10. Crosscutting Blade

You can use these blades to cut across the wood and other related materials with precise and accurate cuts.

What Tools Do You Need To Sharpen Blades

To sharpen circular saw blades by yourself, you need some tools. Here are the most important tools to get the job done:

- Screw Clamp

- A flat file

- Ring Spanner

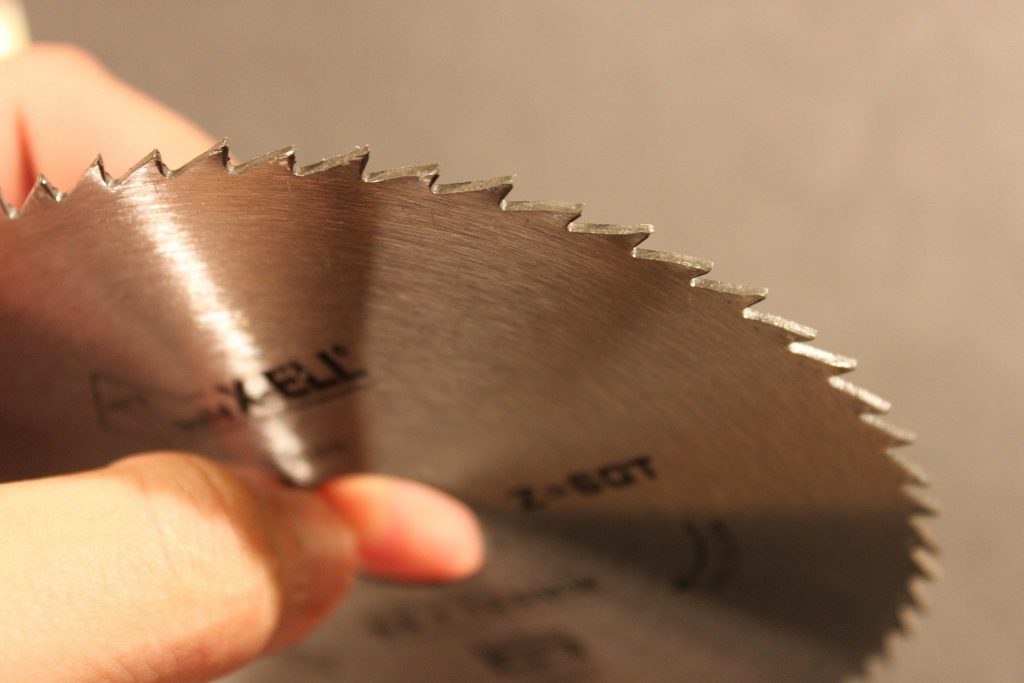

- Dull Saw Blade

- Triangular File

- Pliers

- Safety Gloves

- Safety Glasses

- Wrench

The Easiest Way to Sharpen A Circular Saw Blade

Sharpening a circular saw blade can be done in many ways. However, the easier way saves time and effort.

Not only that but it also works just as well as the other painstakingly long sharpening methods.

Step 1

The first thing you need to do is to remove the blade. Make sure the saw is turned off and that you have checked the blade guard.

It is always advised to wear blade-proof safety gloves when doing so.

Loosen the nut holding the blade in place with a spanner and remove the blade carefully. Make sure you don’t lose the nut.

Step 2

Use two clamps to fix your saw blade to the sharpening table or workplace. Make sure that it is tightly secured in place.

You do this to make sure your blade doesn’t move during the sharpening process.

Screw clamps are the best sort of clamps for this job as they hold the blade and don’t let it vibrate.

Step 3

To keep track of how much of the blade you have sharpened, mark your starting point with a marker. Then proceed to work your way up from the bevel by making four to five up and down movements with your file.

Important: Make sure to tilt the file at a 20-degree angle.

Continue to do this for the whole of the blade and on the other side as well. This ensures that your blade’s teeth are perfectly sharp.

Step 4

Frequently using your saw can cause the teeth at the tips on the blade to become uneven. It is important to file them down to the same level so that the blade cuts evenly. circular saw blade’s teeth with a file.

A flat file works best for this sort of job since it evens out the teeth uniformly.

Make a few horizontal strokes to and fro on the teeth to even them out. Then you’re all set to move on to the next step.

Step 5

The next step is rather tricky but extremely important. The teeth on the circular saw blade need to be set so that they don’t get caught up in the material they are cutting.

Saw-teeth are usually inclined left or right and sometimes have no incline at all.

Make use of pliers to set the saw teeth in the desired direction. If you are going to sharpen a circular saw blade this will be the most important part.

Caution! Do not set the teeth against the direction they were already set at.

Step 6

Finally, now is the time to use the triangular saw file. Now that the teeth have been set and sharpened, we can start to sharpen the blade.

Place the triangular file near the carbide-tipped teeth of the circular saw blade and up to four filing strokes.

Do not file off a lot of the circular saw blade immediately or else you might need to fix the teeth again. Just file it back and forth enough to make it uniformly sharp.

Step 7

Now that the tips of the teeth are fixed and the circular saw blade is sharpened, attach it back to the saw. Be careful when reinstalling the blade on circular saws as handling sharp blades is different from handling dull blades.

Make sure to nut the blade back in place and check if you installed it right.

How To Tell If A Saw Blade Is Dull?

It is difficult to tell when a blade is worth sharpening but the best telltale signs are that the teeth will not look uniform.

You will also notice that the saw isn’t making precise cuts anymore or the material gets caught in the blade. When you see these signs, your circular saw blade needs sharpening.

Circular Saw Blade Sharpening FAQs

Is it worth getting a professional to sharpen a saw blade?

A professional charges a good amount of money to sharpen a saw blade. The professional tools they use seem like the only option but in truth, you can get the same results at home.

Sharpening the saw blades yourself can be just as convenient as getting a professional to do it.

How frequently should I sharpen saw blades?

A blade should be sharpened as soon as it begins to dull significantly. Most blades have a life mentioned on them, like how many cuts or continuous hours it can take on a certain material.

After this period it is generally advised to sharpen the blade again to keep it in good condition.

What are the ways to keep blades from getting dull?

The easiest way to keep a blade from dulling is to have separate blades for separate materials. That is if you can afford it of course.

You can have a blade for wood, tile, metal, ceramic each and they will collectively last you longer between sharpenings. It will also give you cuts that are more accurate.

What is a hook angle on a circular blade?

Hook angle on a circular saw blade is how much forward and backward incline the teeth of the blade have. It’s also the angle at which the teeth meet the material and engage with it.

A positive tooth angle means that the blade will have an aggressive bite. On the other hand, a negative tooth angle means the blade will be less reactive to the material.

Different tooth angles are used for different kinds of blades.

What kind of blades needs the least sharpening?

Carbide-tipped blades need the least amount of sharpening as they are designed in a specific way. Carbide blades have special teeth with a hard coating that protects them from wear.

The tooth count on the blade also significantly impacts how often it would need to be sharpened or you would need to replace it.

Conclusion

Sharpening a circular saw blade doesn’t have to be as hard as it looks. With the proper tools and right method to follow, you can do it as well as a professional.

However, it is important to understand that sharpening your circular saw blade can be fatal if you don’t take the right precautionary steps.

We have included everything you need to know in this guide, we suggest that you read it thoroughly before you get started.