With a drill. Yeah, the answer’s that simple.

Everyone knows how to cut a round hole in sheet metal. Ask a random stranger from the street. He/she will give you this answer without breaking any sweat.

But there’s a catch-

Not everyone knows how to use that drill accurately. Many don’t know how to secure the sheet with clamp (Yeah you need to secure it to avoid problems).

Simply put- ‘How to cut a round hole in sheet metal?’- is a simple question and has a simple answer. But very few people actually know the full answer. And drilling without knowing the full process might ruin your whole work. Or worse you might get hurt in the process.

You have to go through 4 steps to cut a round hole in sheet metal. Messing up any of these steps come with unpleasant consequences.

No worries. We’re here to help you out.

So, let’s drill our way through all the steps-

How to cut a round hole in sheet metal: Follow Few Steps

Step 1: Get Prepared

For this step, you’ll need a compass, ink and a center punch.

At first, locate the center of the whole. Next, use a compass to outline the edge of the hole. Put your ink to the use and mark the hole center. Now, it’s time to use that center punch.

Use your center punch to strike at the center of the hole. This will create dimples in the sheet. And these dimples will hold the drill in place.

Step 2: Use Clamps to Hold the Sheet

Don’t say that you were thinking of holding that metal sheet with bare hands drilling it.

Don’t ever hold metal sheets on your hands while drilling. Always clamp the sheet down.

After clamping the sheet make sure that it doesn’t spin. Many people got injured as the metal sheet spun while drilling.

Also, mask the back of the sheet with tape. This masking will prevent your metal sheet from tear-out. Many people use one-time wooden boards to support metal sheets. In this case, you don’t have to use masking.

Step 3: Choose Your Drill

Choosing drills depends upon some factors.

What is your hole size? How much time do you have? How much force do you want to apply?

Based on the answers to these questions, you can choose your drill. Here we will reveal which drills to use when. So, let’s begin-

Using Twist Drills

This is the most straightforward option for drilling a round hole in sheet metals.

At first start by drilling a small diameter pilot hole. Then, gradually start drilling larger holes. Do this till you get your required hole size.

But this method is highly time consuming and boring. If you want small holes, then this is a great method. But drilling medium to larger holes isn’t this drill’s game.

Our Favorit 2 Twist Drills Bits:

Using Step Drill Bit

Step drill bits can drill holes of several sizes in one operation. This is better than using twist drills. But this drill has some drawbacks.

The first drawback is that this useable in only thin metal sheets. You can easily create large holes in thin sheets by using this drill. Some step drill bits need pilot holes.

However, self-starting step bits don’t need pilot holes for drilling. Moreover, self-starting step bits can create burr-free holes. So, you don’t need to polish holes later on.

We loved this 2 – step drill bit:

- Neiko 10194A Titanium Step Drill Bit (Bestseller)

- CO-Z 5pcs Hss Cobalt Step Drill Bit Set (Favorite Choice)

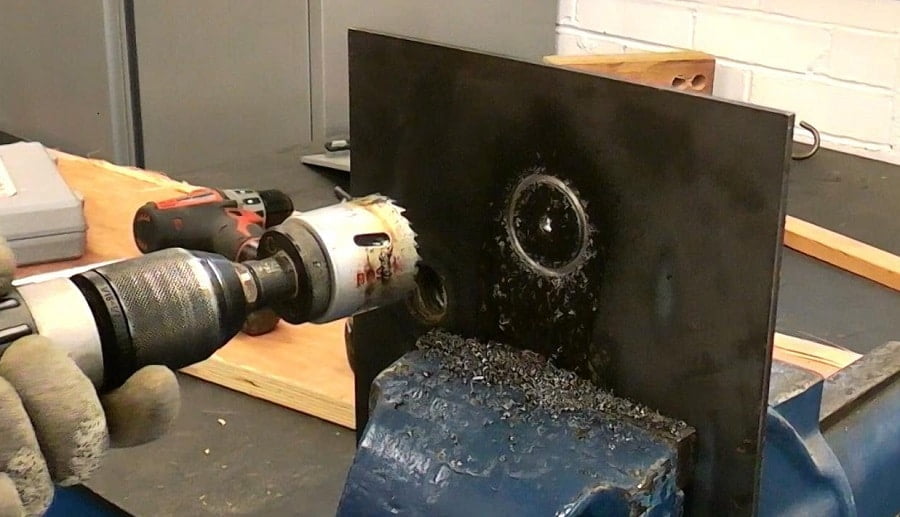

Using Hole Saws

Other drills start cutting from the center. But hole saws cut out the round whole edges. If you use this item, then you have to mark the edges of the round circle.

While using this saw you should use a backboard. This will both support the sheet from teardown and guide the hole saw for better cutting.

You’ll get a table of recommended RPMs for different hole sizes and sheet material from the saw manufacturer.

There’s one drawback of using hole saws. These saws sometimes bind. At that point, the saws grab the workpiece with a lot of force. Sometimes, in that situation, these saws smack out of hand.

So, you have to be extra careful while using these saws.

Check Our Hand Pick Hole saws

Using Portable Hand Punches

This is the perfect item to make perfect holes in a metal sheet. If you’re thinking about the force needed, then don’t worry. The levers increase force amount and you’ll need to put a pretty low amount of force for this.

However, making a hole in thick metal sheets is pretty tough with these hand punches. So, try to keep within the boundaries of thin metal sheets while using this item.

We Got an awesome Portable Hand Punches for metal – Eastwood Deep Metal Hand Punch

Using Other Tools

You can use some other tools too.

Knockout punches, circle cutters are also pretty famous for creating holes in metal sheets.

Step 4: Smooth Out the Hole

Your hole burrs depend on your drill or cutter. Some items cut clean and some create rough and sharp insides.

In small holes, finger twist larger twist drill over the hole. In larger holes use a deburring tool.

Let’s discover some awesome Saws to Cut a Round Hole in Sheet Metal

Bottom Line

Now that you know all about using tools and securing metal sheets, we hope that you’ll face in your work.

Good luck.

Have you thought anything?? Comment below.

Check out more about Hole Saws and how to use them effectively on our complete guides.

Spray water or thread cutting oil from a bottle as you drill to cool the bit. Or Run water from a hose as you drill. Better yet drill with the surface submerged in water.